Introduction to the Failure Analysis Tool

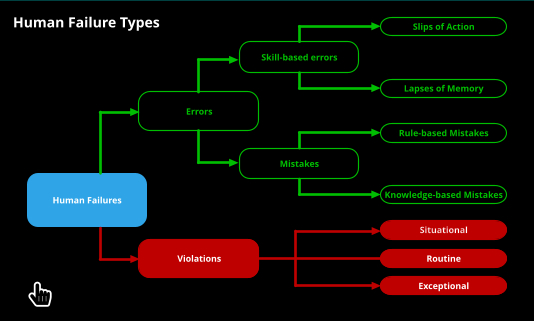

Human failure is per definition a deviation from an accepted standard (rule, procedure, instruction, regulation,

expected action-step etc.) occurring which leads to an undesirable outcome.

This tool focuses on the assessment of immediate possible causes of micro behavioural failures (see diagram)

during the manufacturing process. In this regard, the purpose is to eliminate continued human behaviour failure

before it escalates into a serious quality transgression or safety incident.

PLEASE NOTE: This is a tool to be used to identify the type of failure, it is not an assessment or survey and

therefore there is no submissions of the form required. Once you have identified the type of failure, review the

BBM Portal for possible suggestions to respond or consider doing some root-cause analysis to respond to the

challenges.

Organizations need to address the following aspects regarding safety and quality issues:

•

A measurement of the time taken to identity the human failure with the aim to take the shortest possible

time to diagnose and respond to a

specific situation.

•

The possibility to respond quicker to

situations and the ability to reduce and

prevent human failure by improving

situational awareness.

In using and applying the tool, the causes

and required solutions can be addressed

since the identification of issues with the

reduced response time results in future

preventative human failure.

Orientation Questions

Before looking into the specific types of failures, it is useful to

get some of the background detail so we have a full picture of

what happened, rather than assuming we know all the details.

•

What happened at micro behavioural level? What did the

person do or fail to do that caused the error?

•

What was the failure? When and where?

•

How did it deviate from the expected standard of behaviour?

•

How did it happen?

•

Who else was involved?

•

What was the exact sequence of events before the failure?

•

What is the immediate explanation for why it happened?

•

Did the same behaviour appear in the past?

Failure Diagnosis

Select which of the two blocks is most relevant to the current

failure. From there, answer the questions that follow.

Failure Diagnosis

It appears that an error has been made, which of the following best

describe it (please read each block and then click the one that best

describes the situation):

The incident happened during a

routine or familiar activity in which

the person has the skills to do it,

but attention was diverted by

thoughts or external factors or

possible mind wandering.

There was a failure of planning in

which a decision or action was

expected to achieve the desired

outcome but due to inexperience or

poor information was not

appropriate. The wrong thing was

done believing it to be right.

Failure Diagnosis

It appears there is a skill-based error that has been made, which of

the following best describe it (please read each blue block and then

click the one that best described the situation):

The incident happened during a

routine or familiar activity in which

the person has the skills to do it, but

attention was diverted by thoughts

or external factors or possible mind

wandering.

The action was performed on autopilot,

skipped or reordered a step in a procedure.

The right action on the wrong object, or the

wrong action on the right object. “Action not

as planned.”

The action happened between the plan and

before execution, where the plan should’ve

been stored in the brain. Forgot to do

something, lost place in a sequence, or forgot

the overall plan or intention.

![Close [x]](failure_analysis_htm_files/close.png)

It looks like there has been a slip of action, consider doing the following to

respond:

•

Proper workplace design.

•

Use behavioural check-lists (see Appendix 4 of the BBM White Paper).

•

Discourage interruptions.

•

Reduce external distractions.

•

Effective fatigue management.

•

Mental rehearsal of tasks prior to task.

•

Reinforce memories of rules, procedures and steps by using place-markers

at appropriate points, making it visible, repeating crucial steps etc.

•

Regular quality and safety supervision

•

Encourage mutual observations in the team

![Close [x]](failure_analysis_htm_files/close.png)

It looks like there has been a lapse of memory, consider doing the following to

respond:

•

Proper workplace design.

•

Use behavioural check-lists (see Appendix 4 of the BBM White Paper).

•

Discourage interruptions.

•

Reduce external distractions.

•

Effective fatigue management.

•

Mental rehearsal of tasks prior to task.

•

Reinforce memories of rules, procedures and steps by using place-markers

at appropriate points, making it visible, repeating crucial steps etc.

•

Regular quality and safety supervision

•

Encourage mutual observations in the team

![Close [x]](failure_analysis_htm_files/close.png)

Failure Diagnosis

It appears there is a mistake-based error that has been made, which

of the following best describe it (please read each blue block and

then click the one that best described the situation):

A rule was remembered, or the procedure was

familiar but it wasn’t the most convenient or

efficient. An incorrect application of a good

rule, a correct application of a bad rule, or a

failure to apply a good rule.

There was not sufficient knowledge to perform

the task. A solution was developed that was

incorrectly expected to work. “Trial and error.”

There was a failure of planning in

which a decision or action was

expected to achieve the desired

outcome but due to inexperience or

poor information was not

appropriate. The wrong thing was

done believing it to be right.

![Close [x]](failure_analysis_htm_files/close.png)

It looks like there has been a rule-based mistake made, consider doing the

following to respond:

•

Robust training and regular reviews of required standards and expected

action-steps.

•

Active competency assurance processes.

•

Psychological safety to observe and challenge each other.

•

Proactive supervision.

•

Frequent review of the appropriateness and relevance of rules and

procedures.

•

Independent checking of completed work

![Close [x]](failure_analysis_htm_files/close.png)

It looks like there has been a knowledge-based mistake made, consider doing the

following to respond:

•

Robust training and regular reviews of required standards and expected

action-steps.

•

Active competency assurance processes.

•

Psychological safety to observe and challenge each other.

•

Proactive supervision.

•

Frequent review of the appropriateness and relevance of rules and

procedures.

•

Independent checking of completed work

![Close [x]](failure_analysis_htm_files/close.png)

Failure Diagnosis

It appears that there has been a violation, which of the following

best describe it (please read each block and then click the one that

best describes the situation):

Action was a response to outside factors such as excessive time pressure, workplace design,

insufficient staff, extreme working conditions or inadequate/ inappropriate equipment. A

particular situation made it difficult to comply with a rule or the rule was thought to be unsafe

under the circumstances.

Action was due to a normal way of working within the work group. Routine violation was the

norm in the group. Could be due to:

•

Cut a corner to save time and energy.

•

A perception that the rules were too restrictive.

•

A belief that the rules no longer applied.

•

Lack of enforcement of the rule.

The action was due to an abnormal or emergency situation. The individual felt they had to

break a rule to solve a new problem and was aware that it will be “taking a risk.” A false belief

that the benefits outweighed the risks.

![Close [x]](failure_analysis_htm_files/close.png)

It looks like there has been a exceptional violation, consider doing the following

to respond:

•

Perform risk analysis with team before starting a new or difficult task.

•

Develop a pre-risk based scenario process map for workers to follow.

•

Have an emergency plan in place to manage exceptional events.

![Close [x]](failure_analysis_htm_files/close.png)

It looks like there has been a situational violation, consider doing the following to

respond:

•

Control external factors that might influence failures such as excessive time

pressure, workplace design, insufficient staff, extreme working conditions or

inadequate/ inappropriate equipment.

•

Regularly rehearse exceptional situations and possible options within it

![Close [x]](failure_analysis_htm_files/close.png)

It looks like there has been a routine violation, consider doing the following to

respond:

•

Review rules and their importance regularly.

•

Make rules visible and important points of discussion.

•

Have appropriate reinforcement processes in place for correct and up-to-

standard behaviours, as well as consequence management for extreme or

repeated failures.

•

Check and discuss team and organisational culture of non-compliance.

![Close [x]](failure_analysis_htm_files/close.png)